Innovation

In the flooring world, the same products are offered, made of the same materials and innovation is considered to be improvements, tweaks and updates of the same.

What makes us different? EVERYTHING.

-

Our Materials

We are not made of carpet, tile, hardwood, LVT, cork or bamboo. We are made of a proprietary blend of materials that were originally used for truck bed liners and oil containment ponds. So, when we say we’re safe, durable, and perform well in the toughest conditions – we mean it.

Think of oil containment pond - they protect people and animals from dangerous spills - and so does our flooring. -

Our Double-Sided Tape

When we searched for adhesive, we could not find the grip strength and the longevity we needed, so we worked with an adhesive engineer to create our own materials. The result – self-adhesive flooring tape that can be used on ANY flooring, not just ours.

We also worked with our the adhesive engineer to create seaming tape (to be used beneath seams) and a two-part seaming adhesive to be used on top of seams. The result, when applied properly – our flooring appears almost seamless.

-

Our Management Style

In traditional manufacturing plants, the plant managers “manage” the workers. In our plants, the workers make the decisions. For example, our workers decide what time they will start each day. Because the workers know what the deadlines are for each order, they also decide the number of hours they will work each day, including the weekends.

Most importantly, they determine when the materials meet our quality standards, and they tell us if our flooring needs to be re-done for any reason. Further, if the self-adhesive backing or the CNC cutting is not done exactly right, they let us know and the work is also re-done.

-

Our Testing

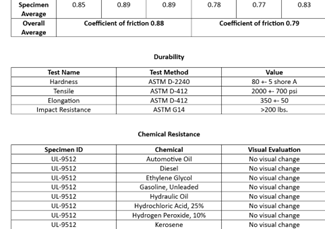

All of our testing is done for 24 hours, not the required 2 hours. Why? Some liquids may damage flooring over a longer period of time. The results – no liquids (including iodine, betadyne, grease, urine, chlorine and more) harm our flooring – with one exception – brake fluid will soften our materials, but when removed, our flooring will go back into its original composition.

-

Our Customization

Clients often ask us what colors we offer. The answer is – you guessed it – ANY color. While we have six standard colors, we can match any RAL K5 color code.

While we have standard lengths of 25’, we can manufacture up to 40’ to avoid seams.

We offer self-adhesive options for our safety striping and recycled rubber tiles.

We also can customize the amount of aggregate you prefer – light (preferred for bare feet or paws), standard, or heavy (used for sports facilities and industrial applications, as needed).

Lastly, we can cut your logo into the flooring, matching your corporate branding standards.

-

Our Solutions

Our solutions were all created based on client needs.

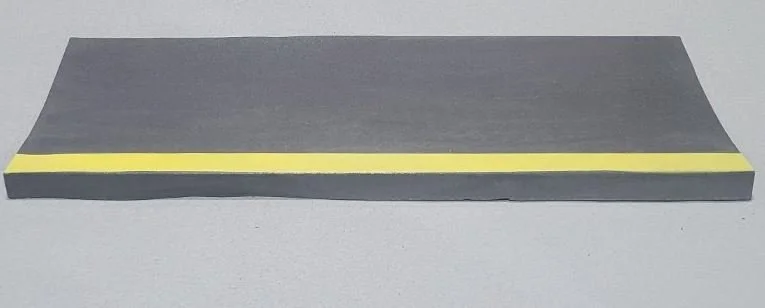

Workers were falling on slippery yellow tape. We created safety striping that will help keep your workers safe from slipping and falling – and there is no need to replace it every 6 months, like thin tape or painted lines. It is warrantied for years!

See more examples below:

Our Products

-

Outdoor Stair Treads

A professional stadium needed treads for their fans’ seating. Slip-resistant, weatherproof stair treads did not exist – until we created them! -

Rubber Tiles

A retail chain needed slip-resistant flooring that could be applied in freezing temperatures without turning off the freezers and losing the food contained within them. They wanted them to be applied quickly and easily. We produced recycled rubber tiles with self-adhesive backing that can be applied and walked on immediately – in freezing temperatures. -

Heavy Slip-Resistance

A client needed flooring for their manufacturing facility where mold release materials fall from production onto the floor. Our standard materials did not meet their needs, so we created heavy slip-resistance – problem solved!If you have a safety need, contact us. If we don’t have a solution, we just may develop a product that will meet – or exceed – your expectations.